C.S.T. SERVICES ALBUM- HMI PROJECTS- BAKERY OVEN DISCHARGE CONTROL

This page has a few images from the bakery oven discarge control project

Last Update November 26, 2006

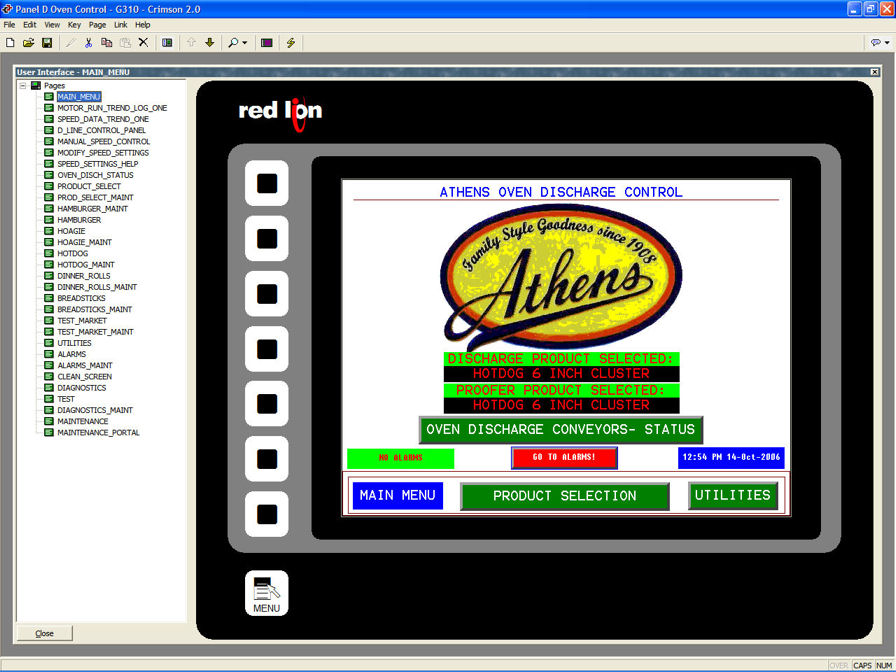

THE FOLLOWING SCREENSHOTS ARE FROM RED LION CRIMSON 2 HMI SOFTWARE FOR AN "OVEN DISCHARGE PROJECT" WE DID FOR A LOCAL BAKERY EARLY 2006:

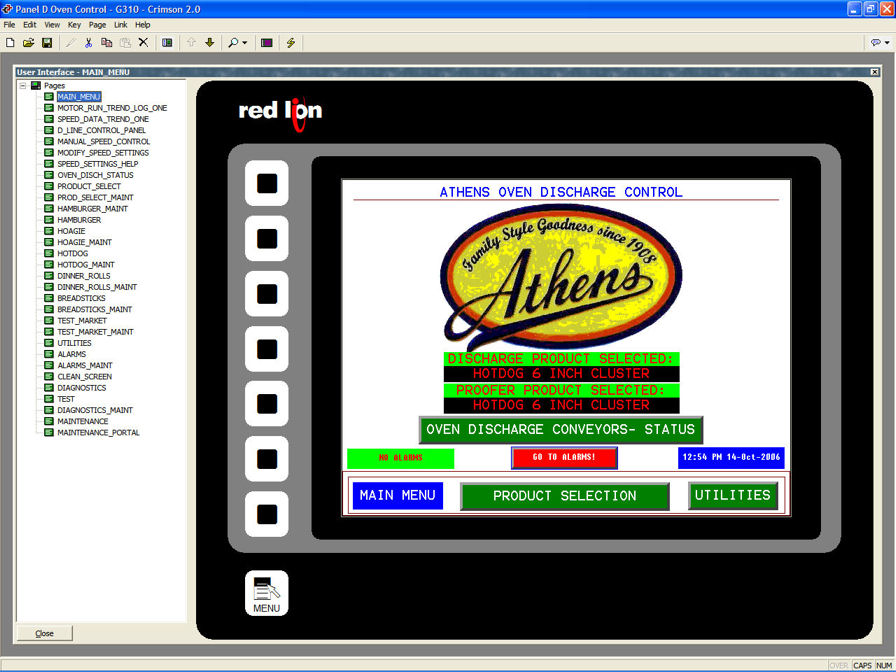

The scope of this project was to install a system of speed control for 5 conveyors for the oven discharge and "de-panning" of the bread products automatically.

There are about 21 different products involving over a dozen sizes of pans. The conveyor "traffic" with constant speed conveyors caused major head aches

with pan jams and an inconsistent rate of product going to the bun cooler and bagging lines.

By installing VFD's (Variable Frequency Drives) to control the conveyor motors and programming the PLC (Programmable Logic Controller) and

HMI for "recipe" selection we were able to overcome these issues. It also involved conveyor removal, modifications, relocation, re-sprocketing

and other mechanical changes. These mechanical issues were handled by another contractor.

C.S.T. SERVICES performed the electrical work and automation. The touch screen is 10" diagonal LCD. The PLC is GEFANUC 90-30 expansion rack system.

THIS IS THE MAIN MENU PAGE OF THE RED LION G310 HMI TOUCH SCREEN WHICH CONTROLS THE NEW OVEN DISCHARGE SYSTEM.

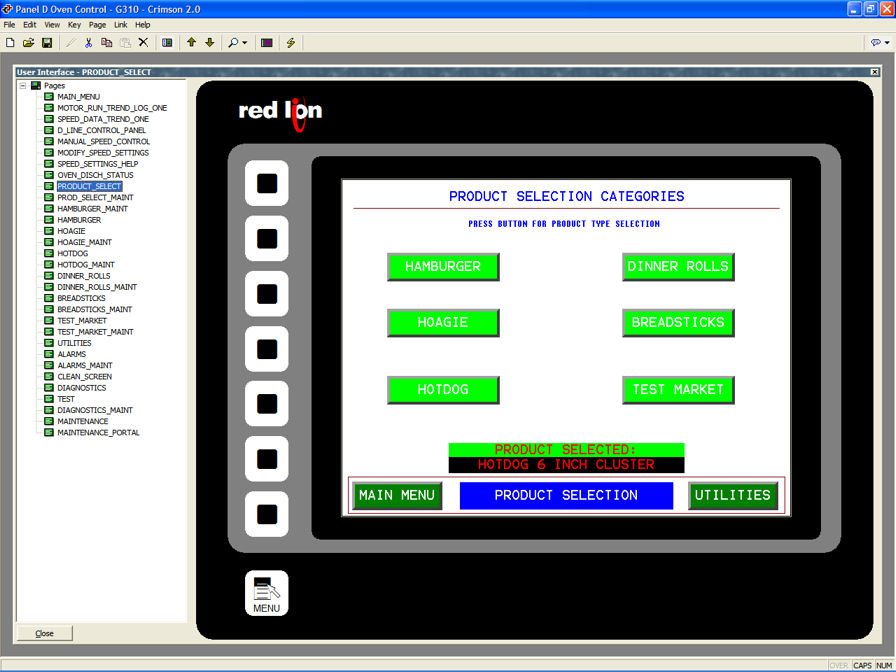

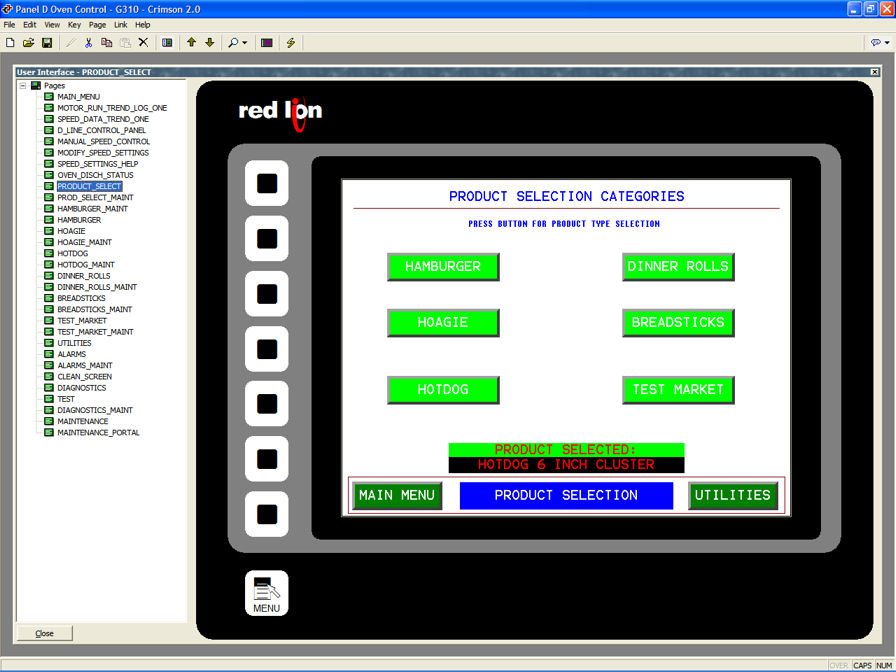

THE NEXT SCREEN IS THE MAIN PRODUCT SELECTION PAGE. THE OPERATOR SELECTS THE CATEGORY OF PRODUCT,

THEN THE SPECIFIC PRODUCT ON THE NEXT SCREEN.

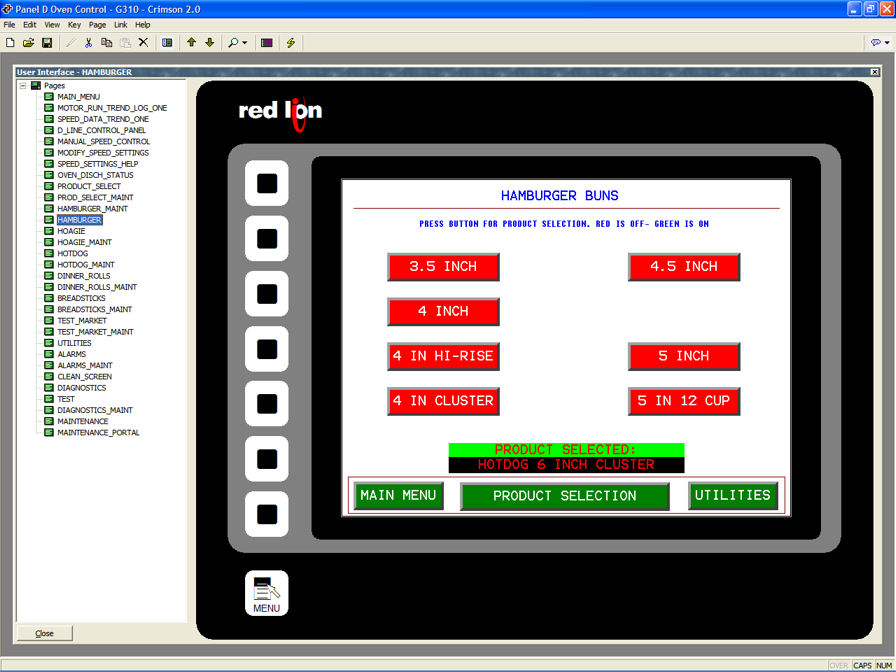

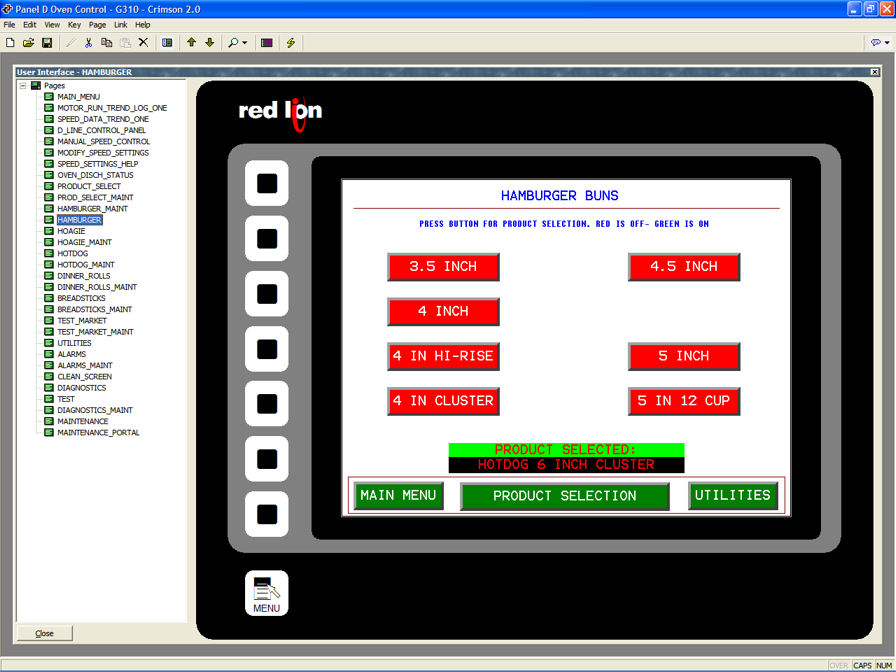

THE NEXT SCREEN IS FOR HAMBURGER BUNS. THE OPERATOR CAN SELECT THE SIZE OF BUN COMING OUT OF THE OVEN.

When the product being discharged is selected, a different group of analog pre-set speeds is used in the PLC which helps reduce the

amount of pan jamming and also creates the right gaps between pans and products.

The result is a more consistently spaced flow of buns to the cooler and to the bagging line.

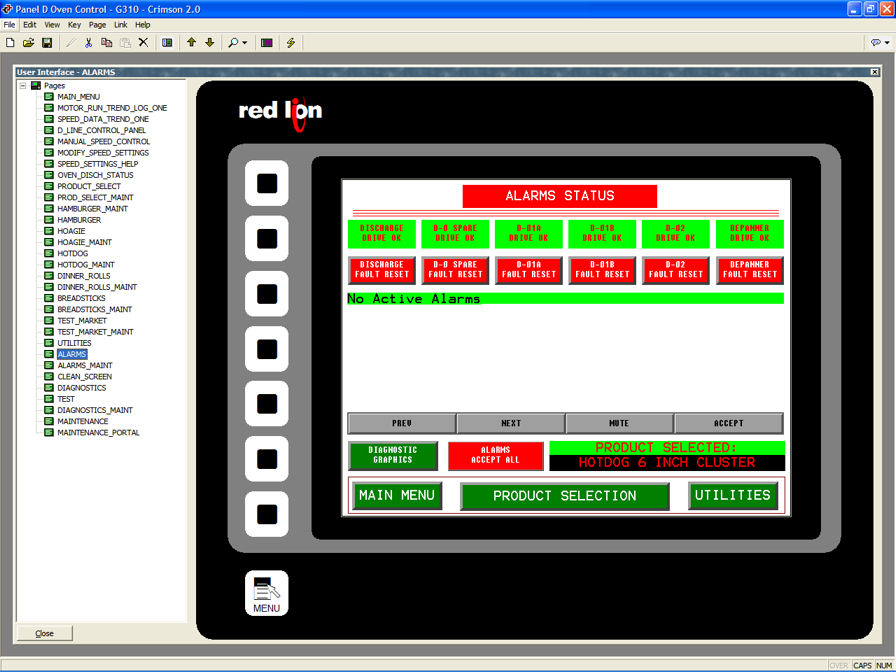

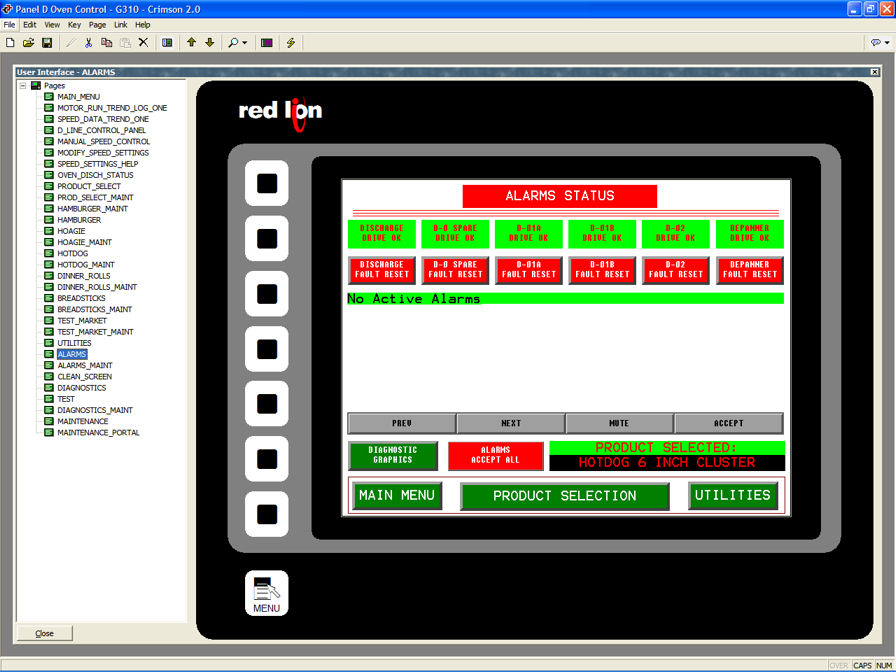

THIS IS THE ALARM SCREEN WHICH WILL POP UP AND SHOW THE ALARM. IF A VFD TRIPS IT CAN BE RESET ON THIS SCREEN.

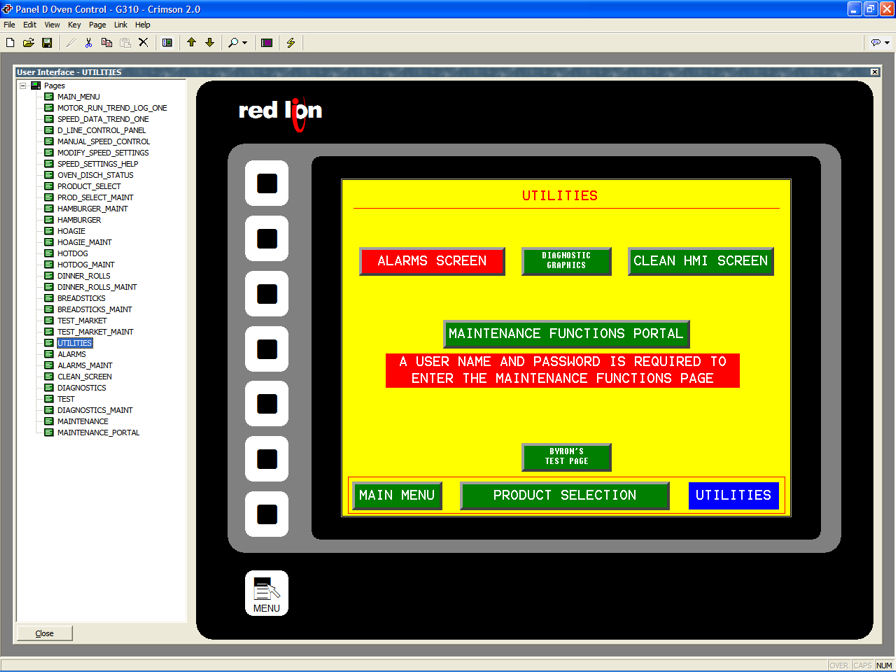

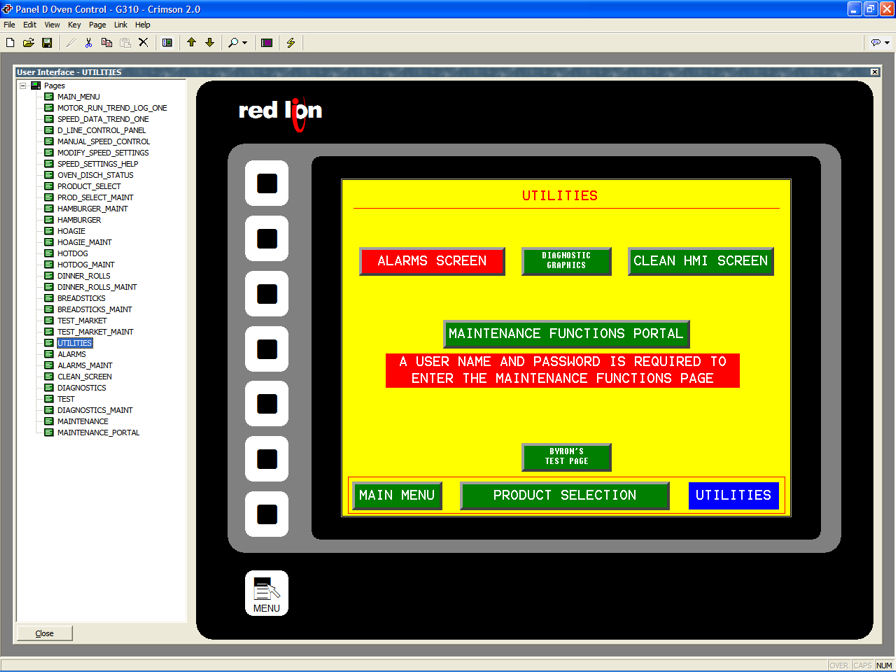

THE NEXT SCREEN IS A PORTAL TO MORE UTILITY FUNCTIONS. IF THE MAINTENANCE FUNCTIONS PORTAL BUTTON IS PRESSED,

A POPUP KEYPAD APPEARS REQUIRING A USER NAME AND PASSWORD TO CONTINUE.

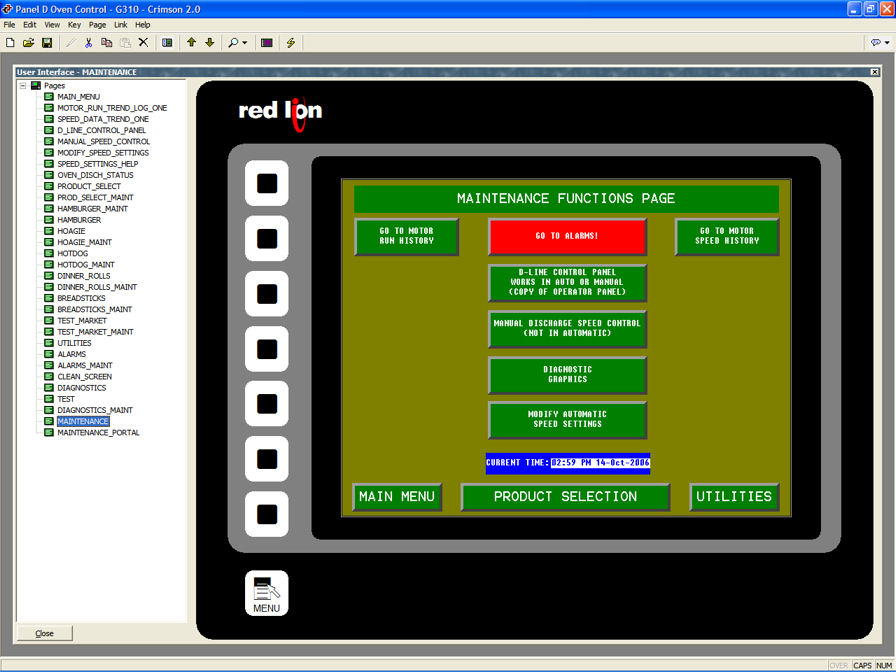

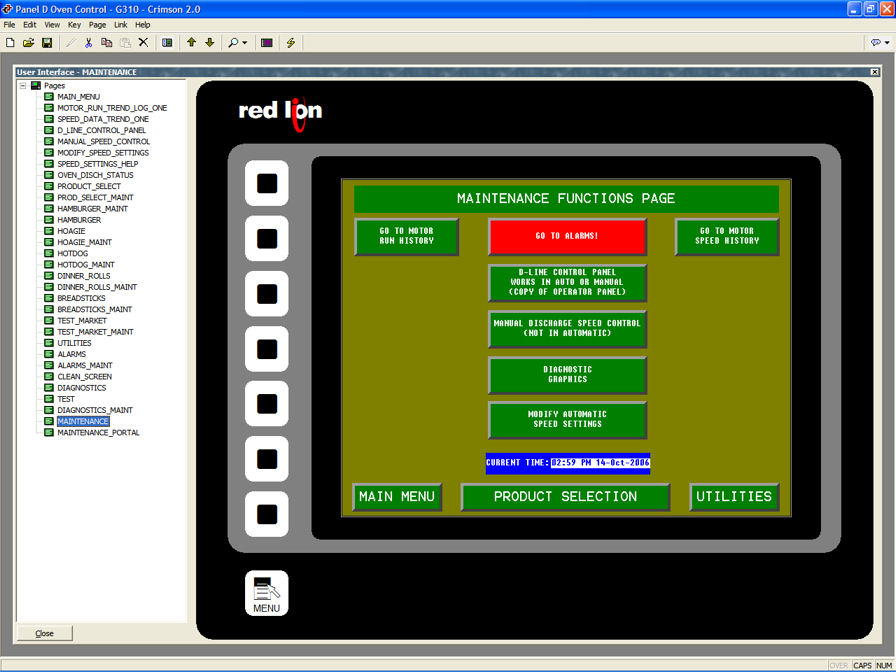

THIS SCREEN IS FOR MAINTENANCE FUNCTIONS. IT IS FOR MANAGEMENT, SUPERVISORS AND MAINTENANCE PERSONNEL.

USER NAME AND PASSWORD REQUIRED.

The system also has the capability of logging users with time and date stamp so management can see who has made any changes to the system and when.

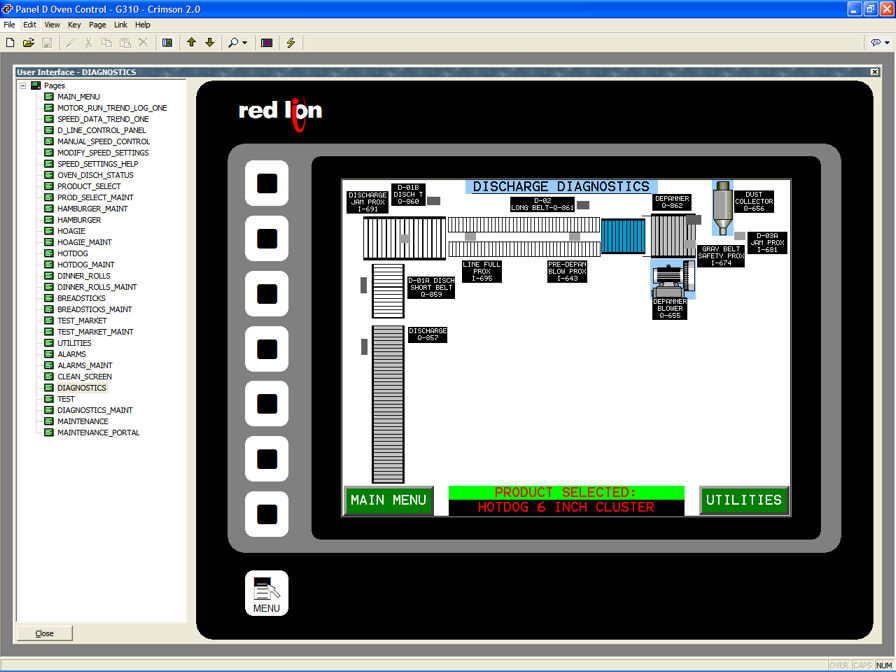

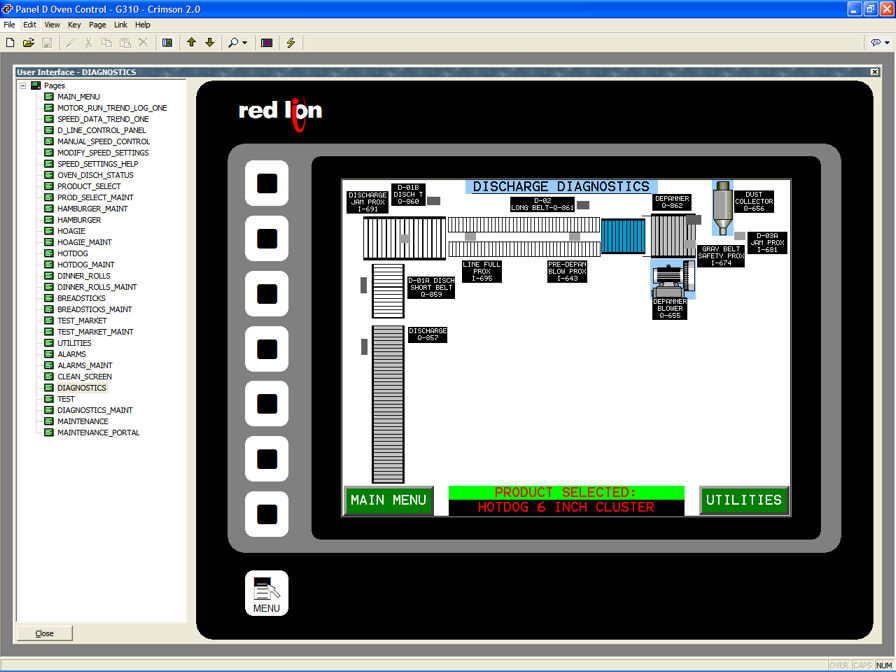

THE NEXT SCREEN IS FOR MAINTENANCE PURPOSES. IT ALLOWS ANY PERSONNEL TO SEE LIVE DATA AT THE DISCHARGE AREA.

THE CONVEYOR BELTS ARE ANIMATED AND MOVE WHEN RUNNING. THE PROXIMITY SWITCHES AND MOTORS TURN GREEN WHEN ON.

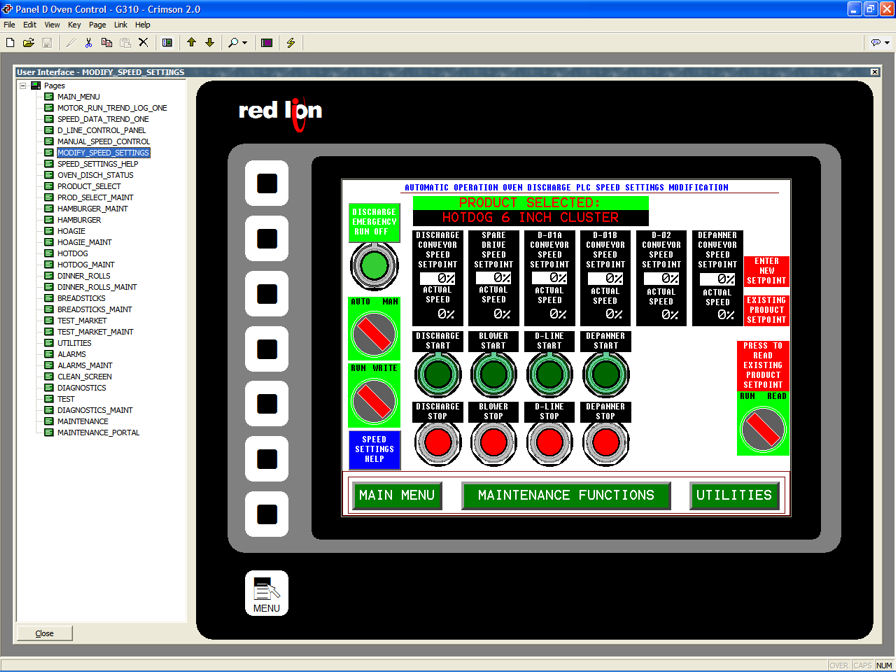

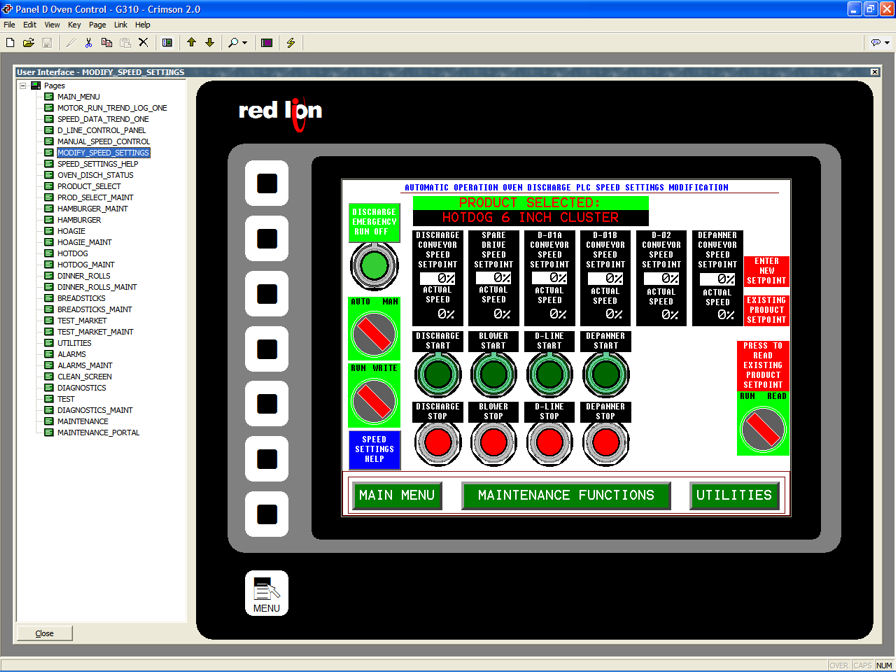

THE NEXT SCREEN IS FOR ADJUSTING THE SPEED SETTINGS FOR EACH VFD BY WRITING THE NEW VALUES TO THE PLC.

IT ALSO HAS A FEATURE FOR READING THE EXISTING VALUES FOR THE SELECTED PRODUCT.

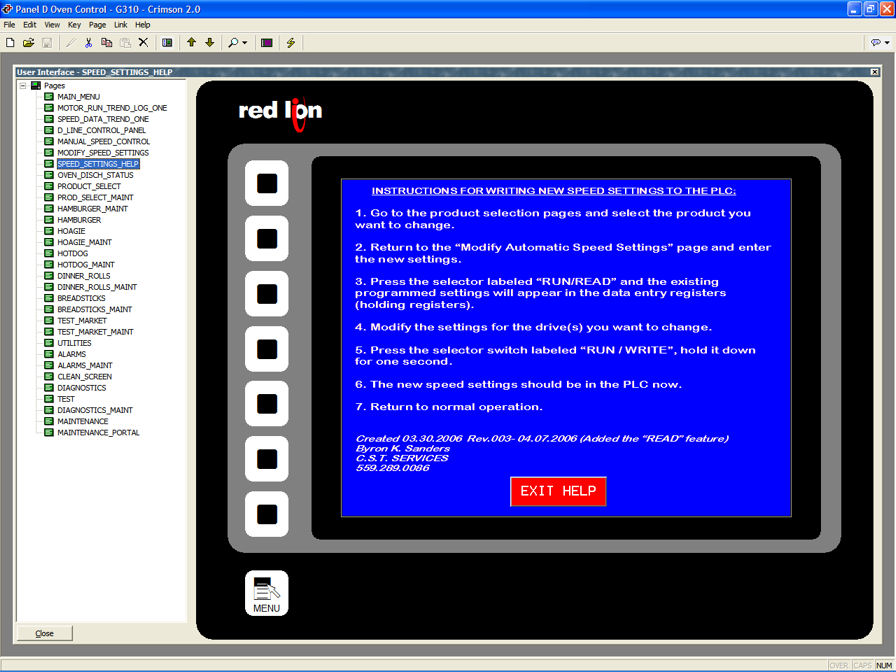

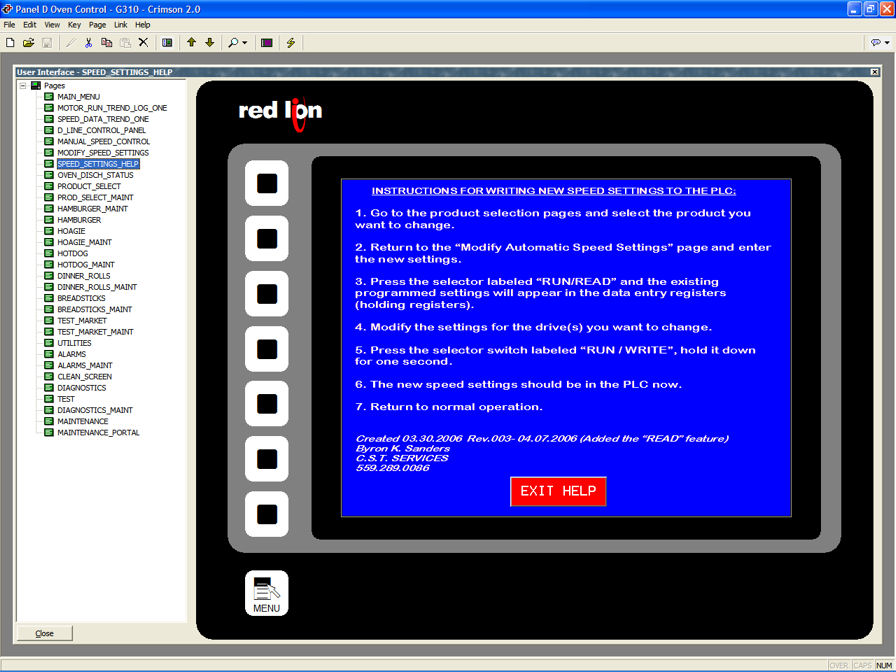

THE NEXT SCREEN PROVIDES HELP FOR ADJUSTING THE SPEED SETTINGS.

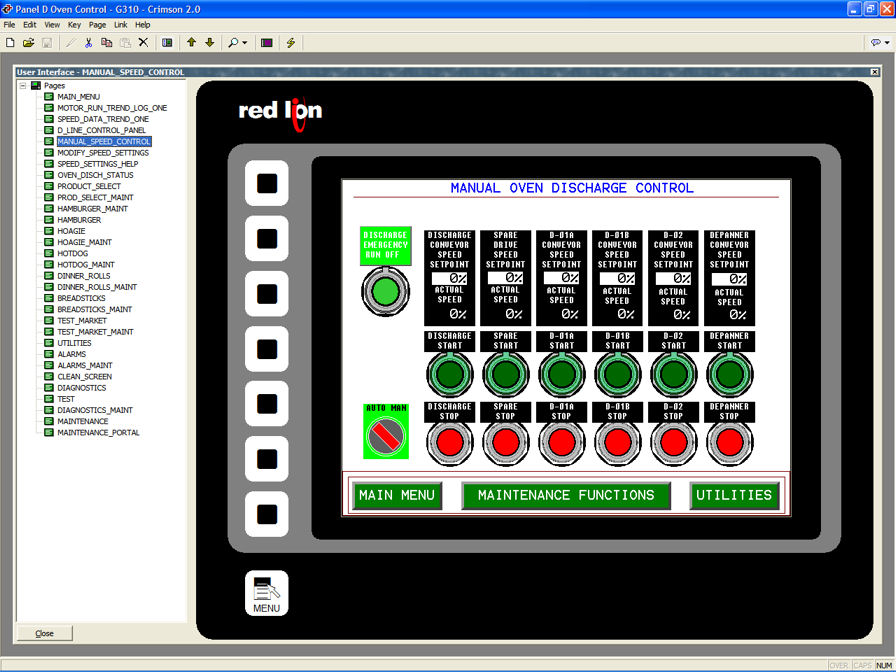

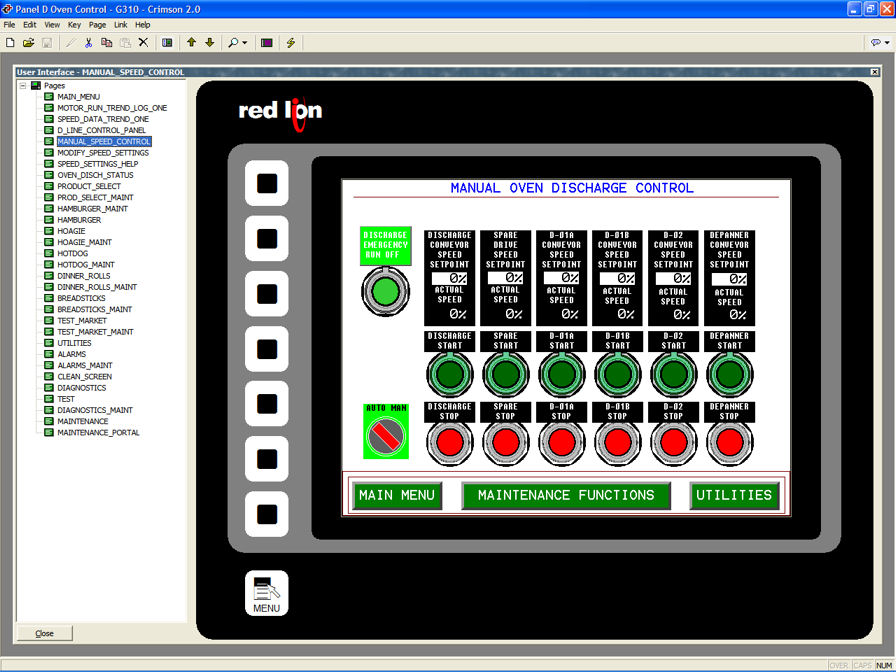

THE NEXT SCREEN PROVIDES FOR MANUAL SPEED CONTROL. THIS IS FOR MAINTENANCE AND TESTING. IT IS PASSWORDED.

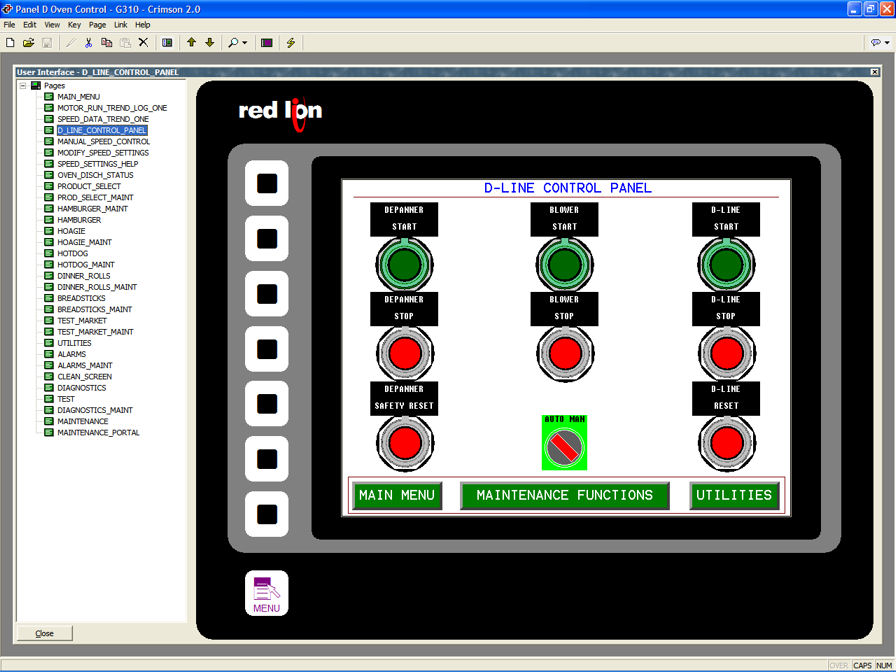

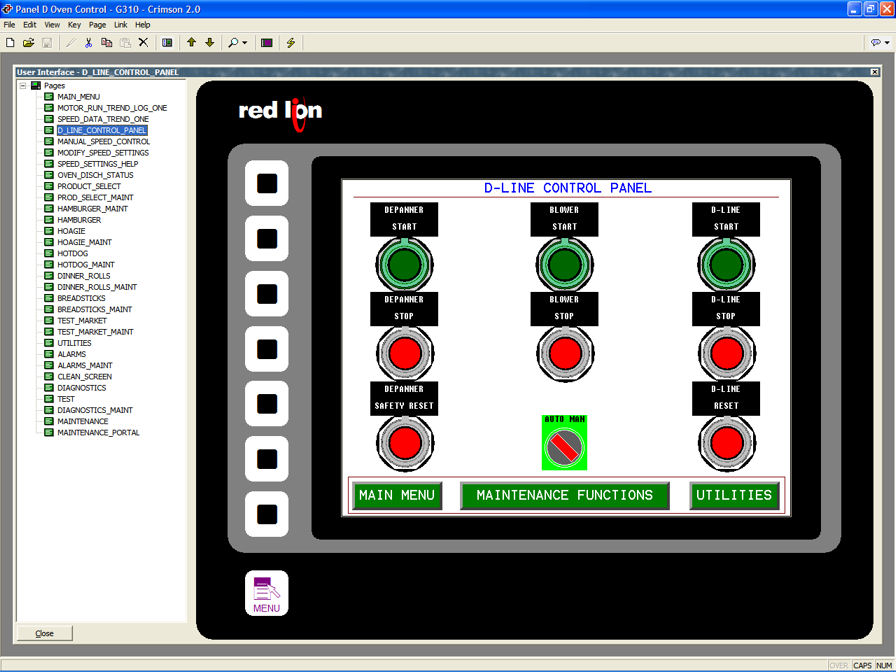

THE NEXT SCREEN PROVIDES FOR AUTO OR MANUAL CONTROL OF THE "D-LINE". THIS IS A REPLICATION OF A REALWORLD OPERATOR PANEL BY THE "DEPANNER".

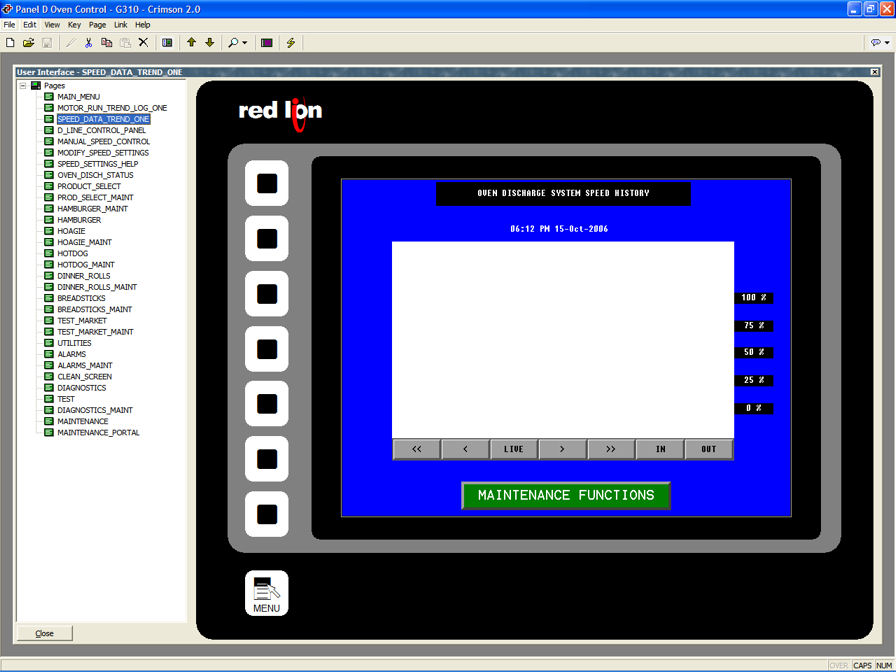

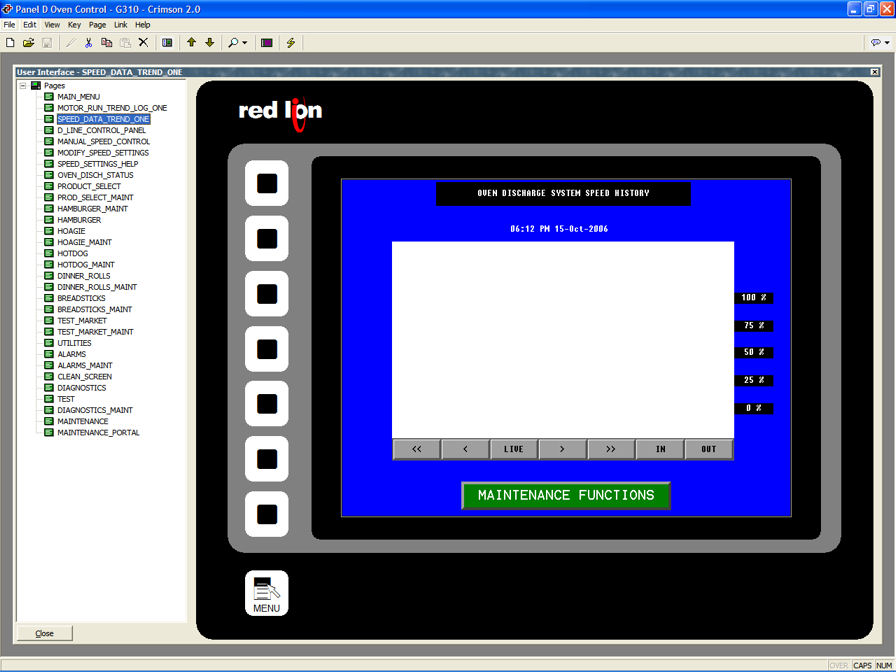

THE NEXT SCREEN IS A "TRENDING" PAGE WHICH TIME AND DATE STAMPS THE SPEED SETTINGS OF THE 5 MOTORS FOR OVEN DISCHARGE.

THIS IS USEFUL FOR MANAGEMENT TO DETERMINE ISSUES WITH PRODUCTION. WE ALSO HAVE A TREND PAGE FOR MOTORS ON AND OFF STATUS.

The trends are saved by Red Lion to an on board Compact Flash card- 1 G.B. Periodically the information can be sent to a decicated P.C. for data collection in CSV format (EXCEL).

COMMENTS: The G3 series of Red Lion HMI's have the following features:

Built in web server- with custom webpage ability

Supports remote access for control of the HMI on a PC or laptop via an Internet Browser

Supports 4 simultaneous multi-branded PLC connections and I/O mapping between them

Built in programming in "C"

Built in Ethernet; initial configuration via USB or SERIAL; 5 serial ports- RS232, 485, and MODBUS

For more information contact the Red Lion website:

http://www.redlion.net

CONTACT C.S.T. SERVICES FOR HELP ON YOUR NEXT AUTOMATION PROJECT! RETURN TO THE FRONT PAGE FOR OUR CONTACT INFORMATION.

RETURN TO C.S.T. SERVICES MAIN PAGE

All rights reserved by Byron K. Sanders and C.S.T. SERVICES