C.S.T. SERVICES ALBUM- HMI PROJECTS:

ACALA COTTON GIN CONTROL- HURON GIN

AUTOMATION OF THE PRIMARY FUNCTIONS:

MODULE FEEDER AND GINSTANDS

This page has a few images of the cotton gin automation project we collaborated on in Huron, California

Last Update Sunday November 26, 2006

The scope of this project was to automate some of the manual functions, replacing push buttons and other manual operations.

We participated in this project as a sub contractor. Our role was primarily systems integration, HMI, and supervision of the primary contractor's electricians.

Since the original project, we have been invited to make changes to the control system, and repair problems from equipment failures, and add other features.

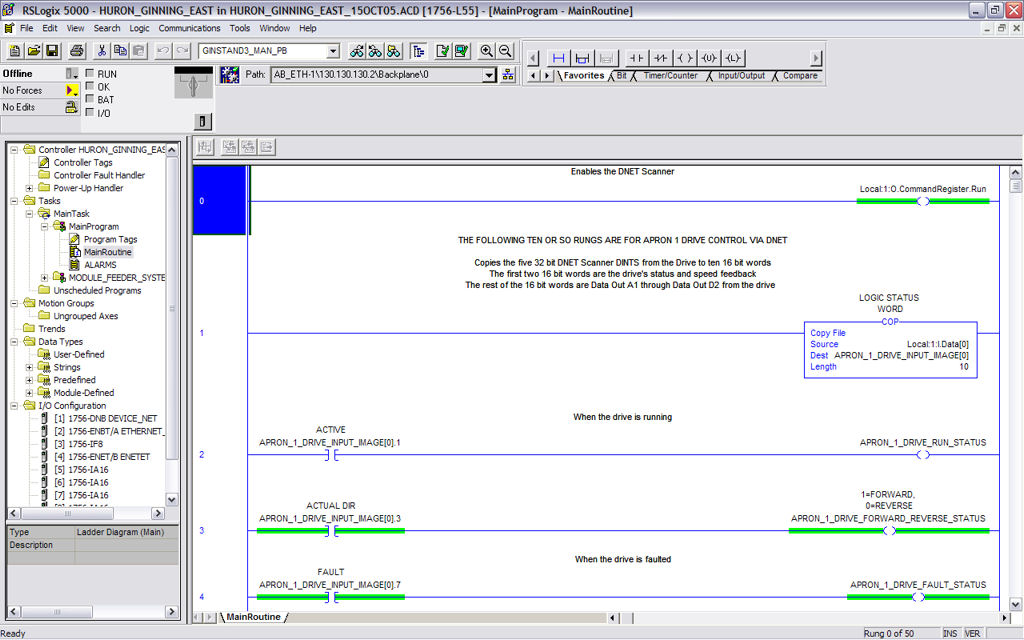

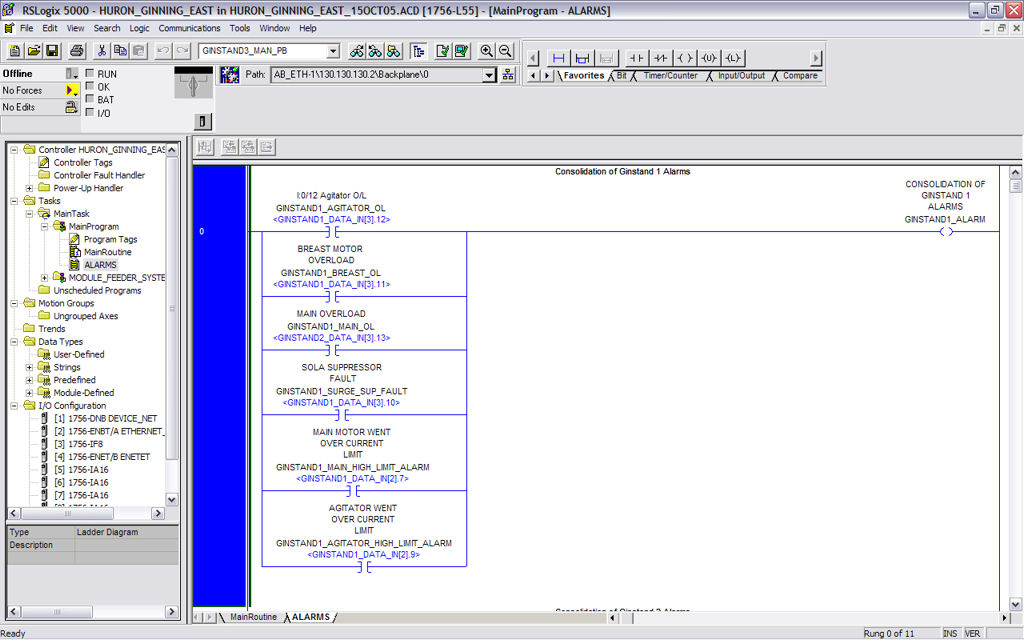

The following screen shots are of some of the HMI and PLC logic screens using Allen Bradley RSLOGIX 5000; RSVIEW32; DEVICENET. We utilized an Allen Bradley

20 inch TOUCH MONITOR which uses a "SALT" driver from the board manufacturer for the touch technology.

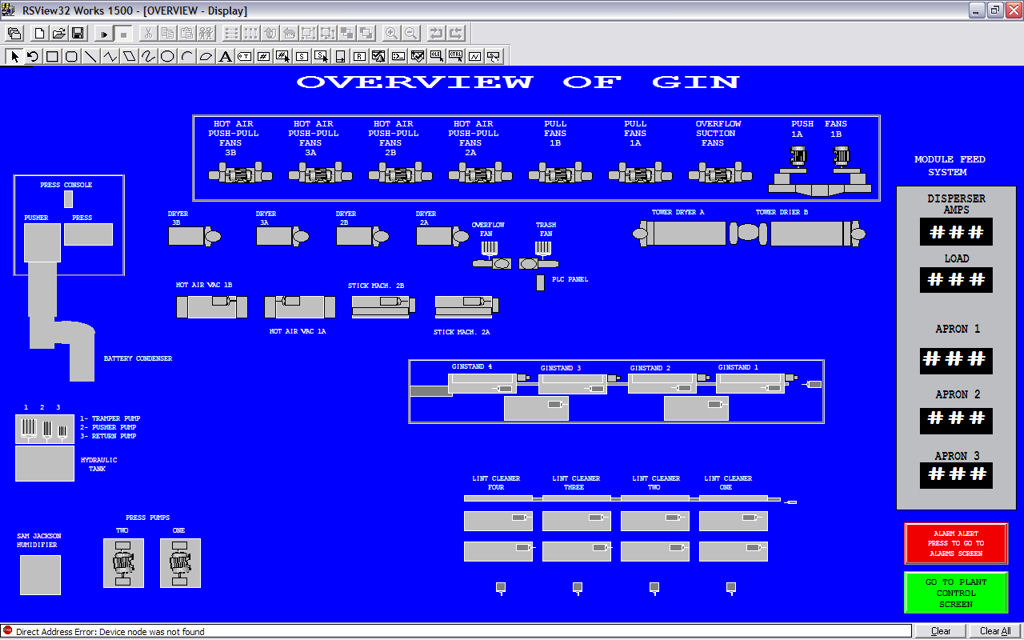

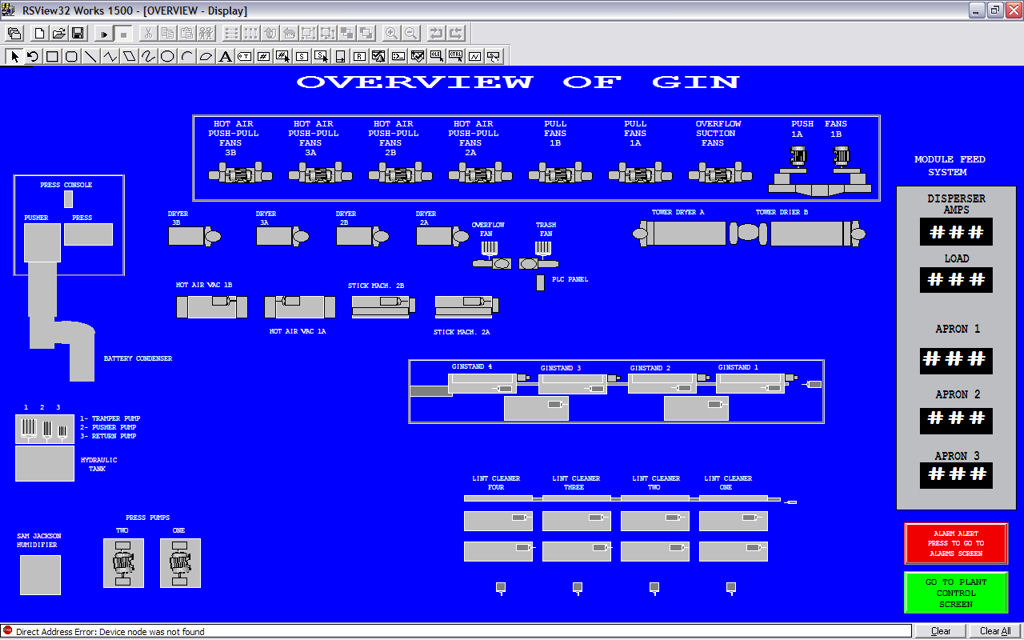

THE NEXT SCREEN IS THE MAIN PAGE- THE PLANT OVERVIEW PAGE

THIS IS THE MAIN OPERATION SCREEN- THIS SCREEN GIVES THE "GINMASTER" (GIN OPERATOR) THE ABILITY TO CONTROL MOST OF THE GIN FUNCTIONS FROM ONE SCREEN.

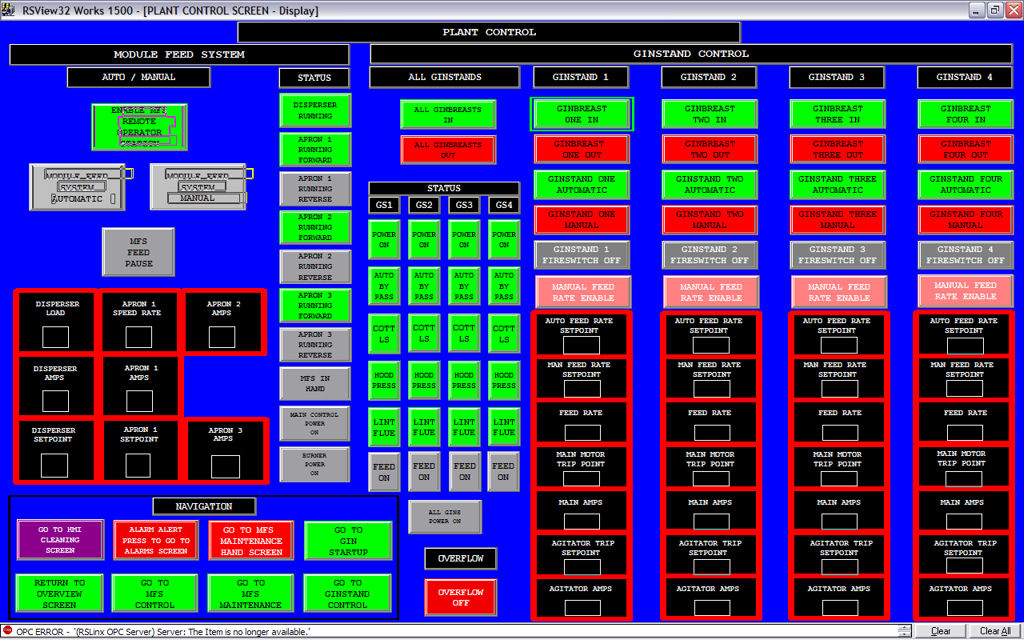

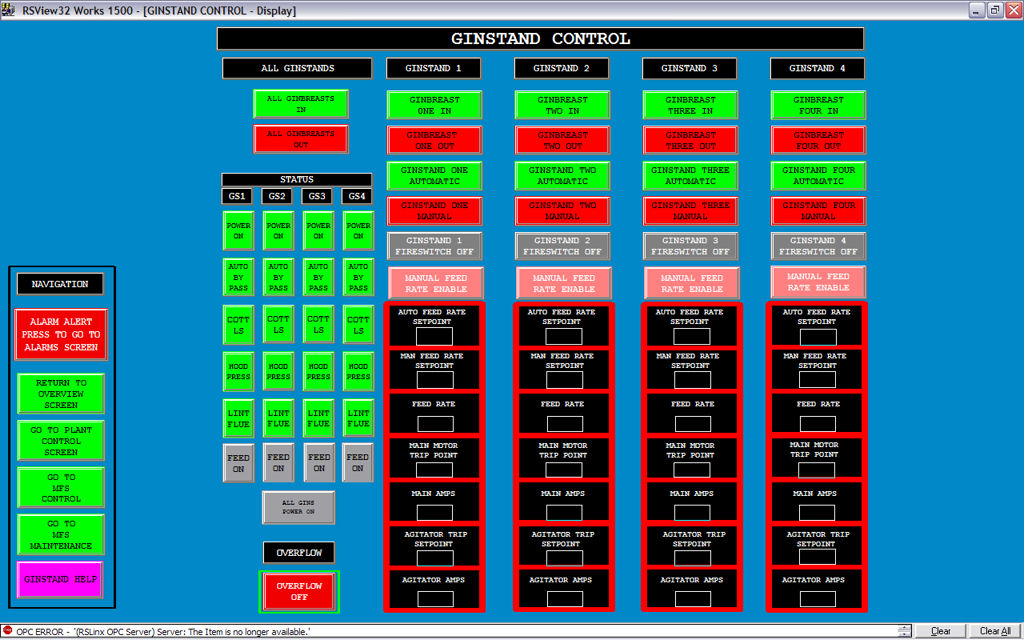

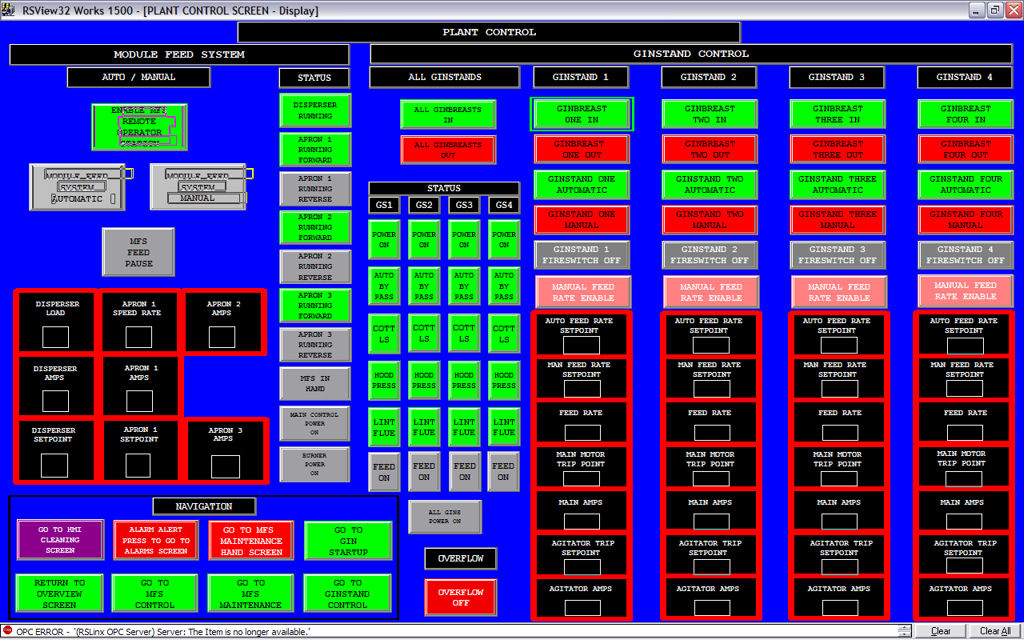

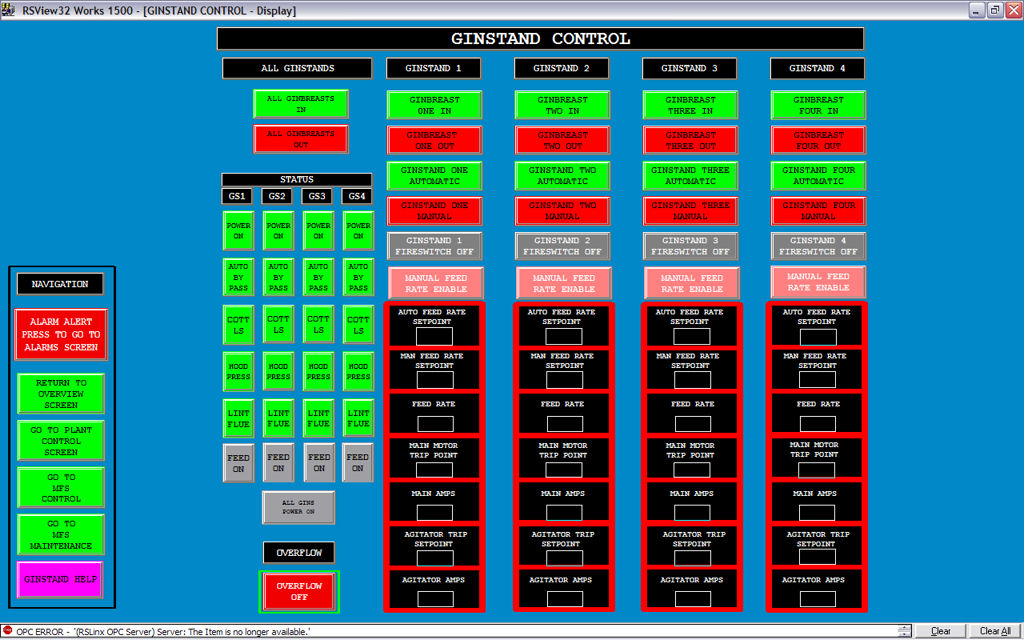

THE NEXT SCREEN IS MAIN SCREEN WHICH THE GINMASTERS USE TO START THE COTTON GIN

THIS ALLOWS THEM TO START THE GIN, THEN THEY CAN GO TO THE MAIN PLANT CONTROL SCREEN

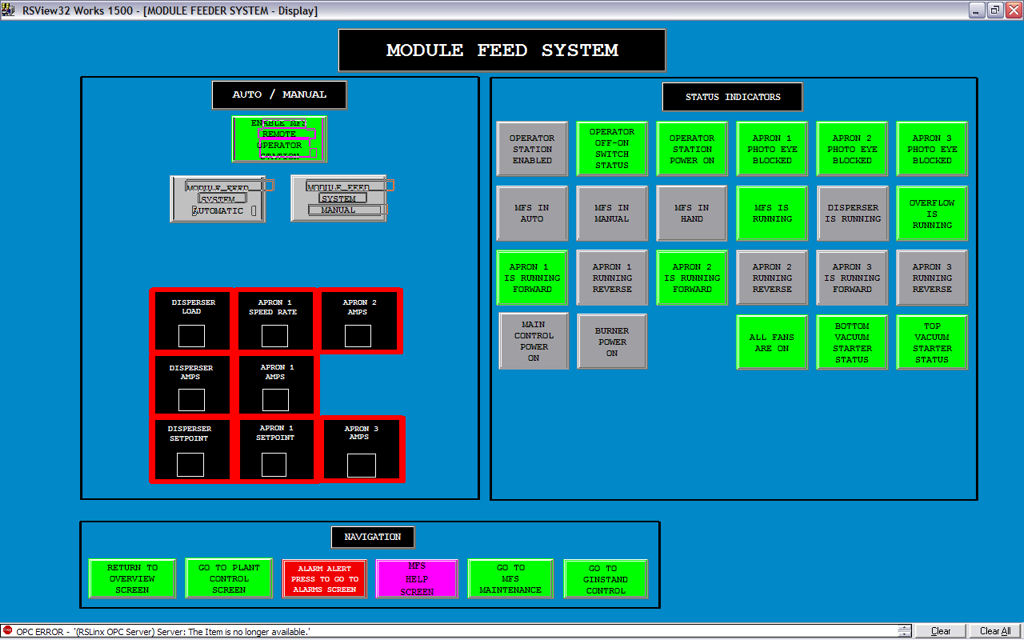

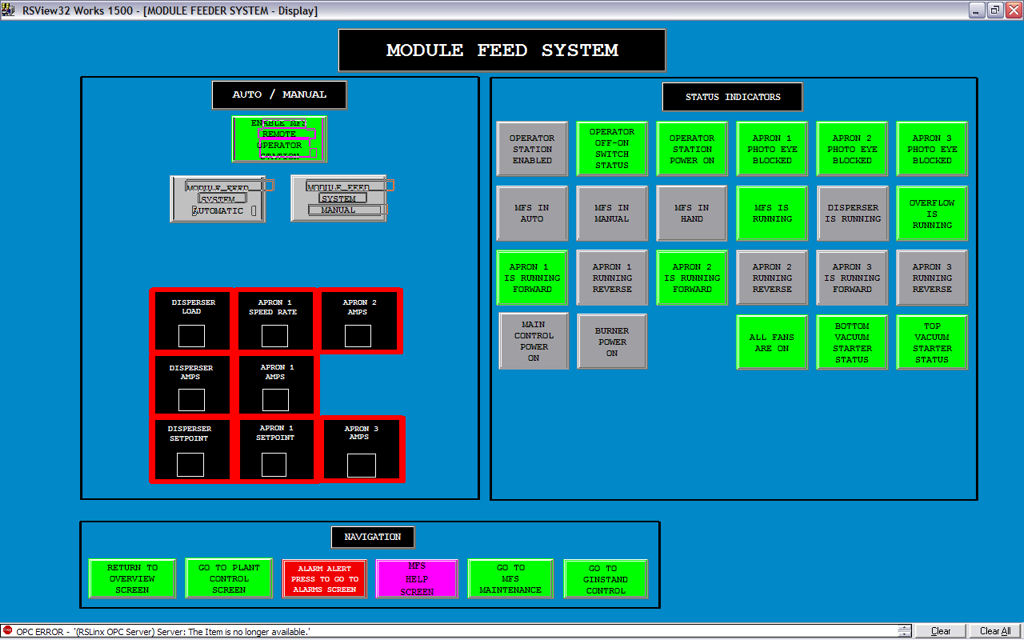

THIS SCREEN IS WHERE THE GINMASTER WILL START THE MODULE FEED SYSTEM "MFS" WHICH FEEDS THE COTTON MODULES INTO THE "DISPERSER" AND BREAKS THEM UP

INTO SMALL PIECES AND THEY ARE DRAWN BY VACUUM PRESSURE INTO THE DUCT WORK TO THE DRYERS AND THEN THE GINSTANDS WHICH TAKE THE SEED OUT FROM THE COTTON

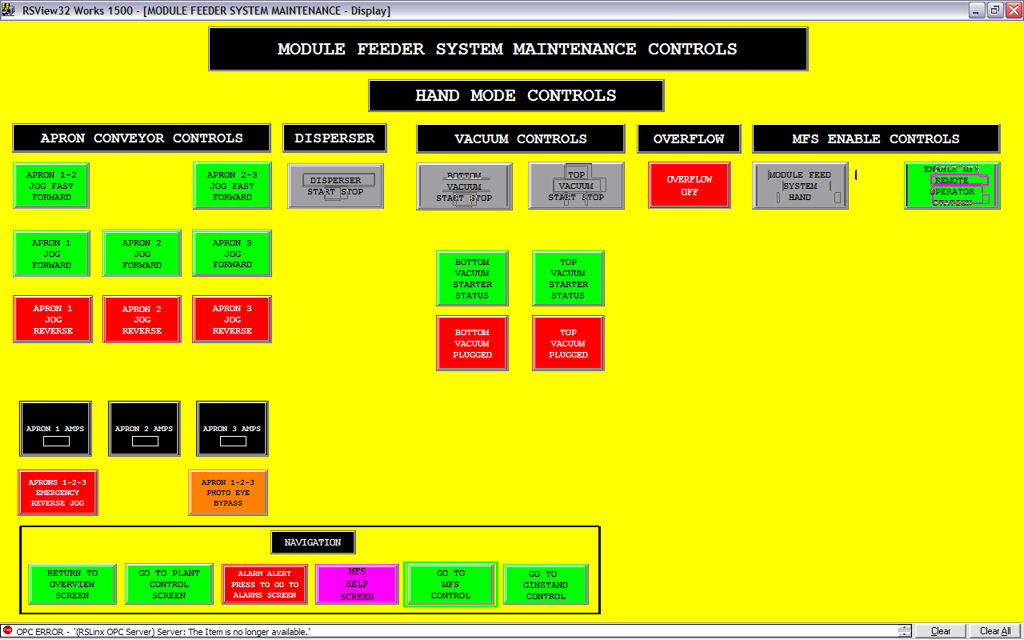

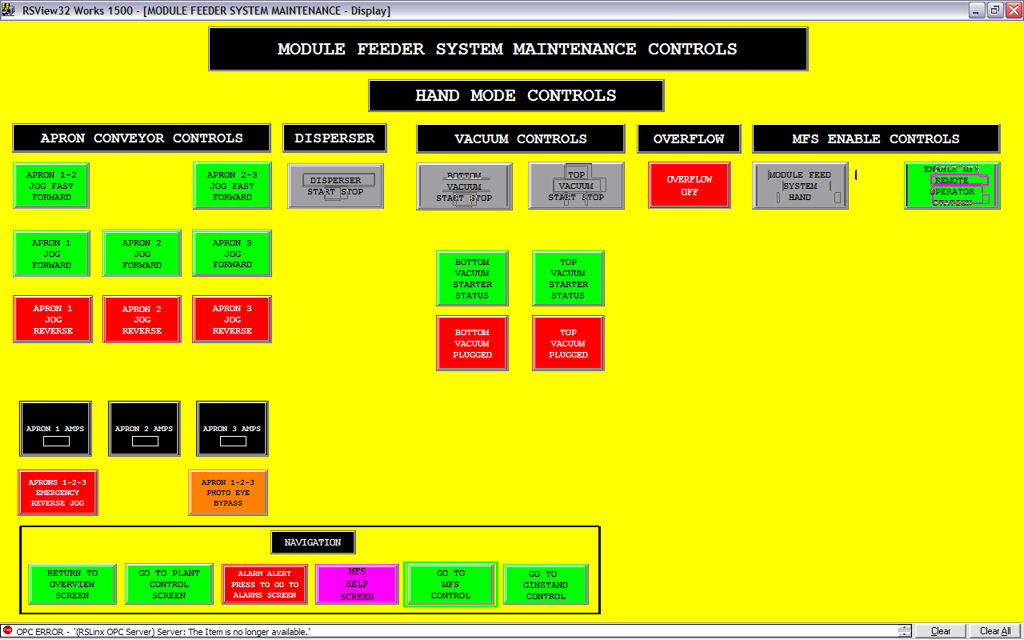

THE NEXT SCREEN IS FOR MFS MAINTENANCE PURPOSES. IT ALLOWS QUALIFIED PERSONNEL TO MANUALLY CONTROL THE SYSTEM.

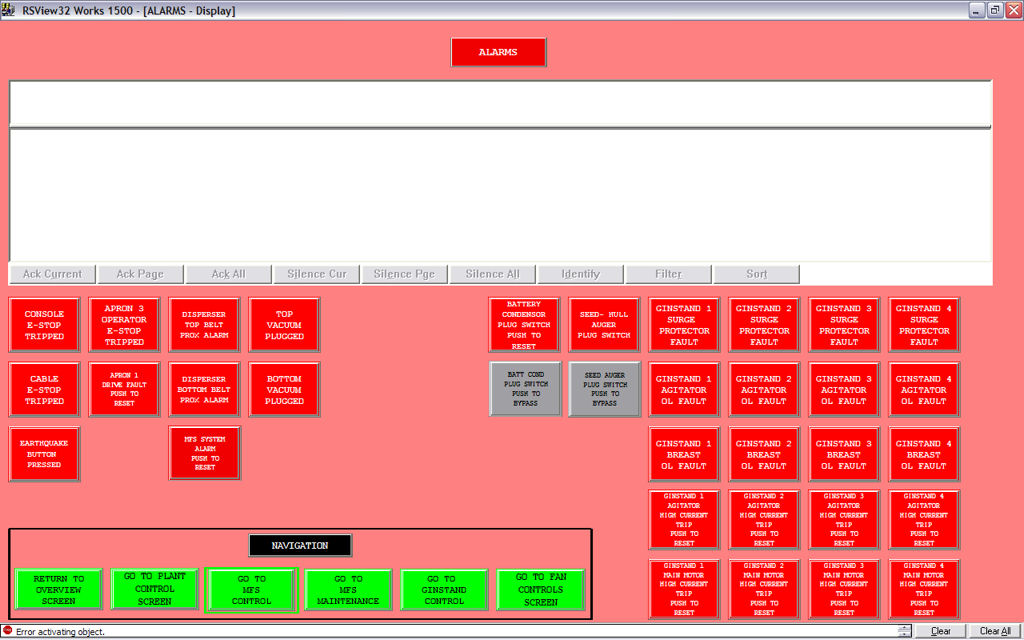

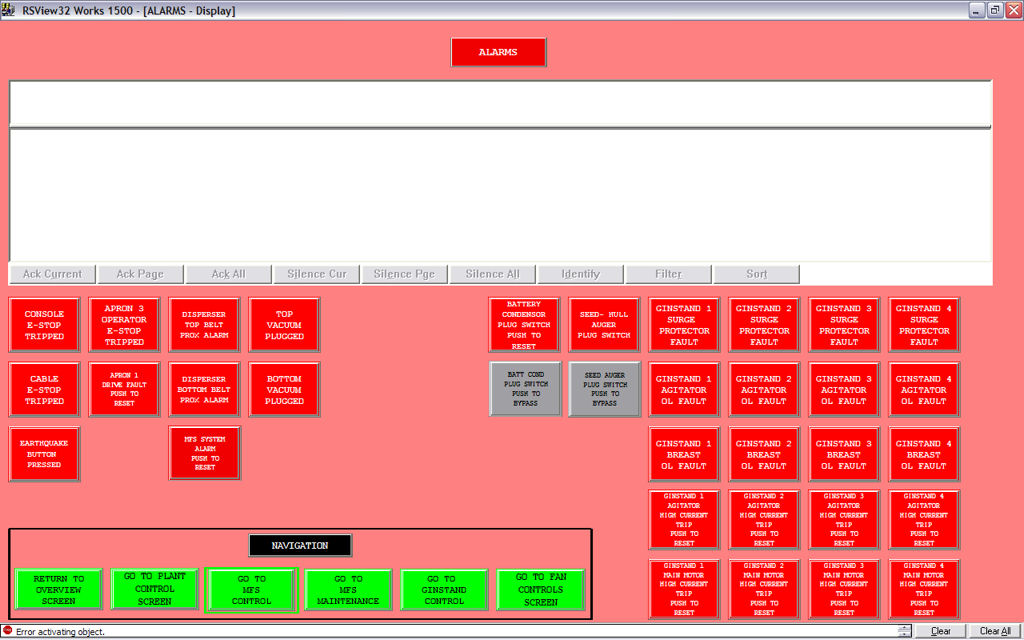

THE NEXT SCREEN IS FOR ALARMS MANAGEMENT. PERSONNEL CAN SEE THE ALARMS AND RESET THEM FROM THIS PAGE

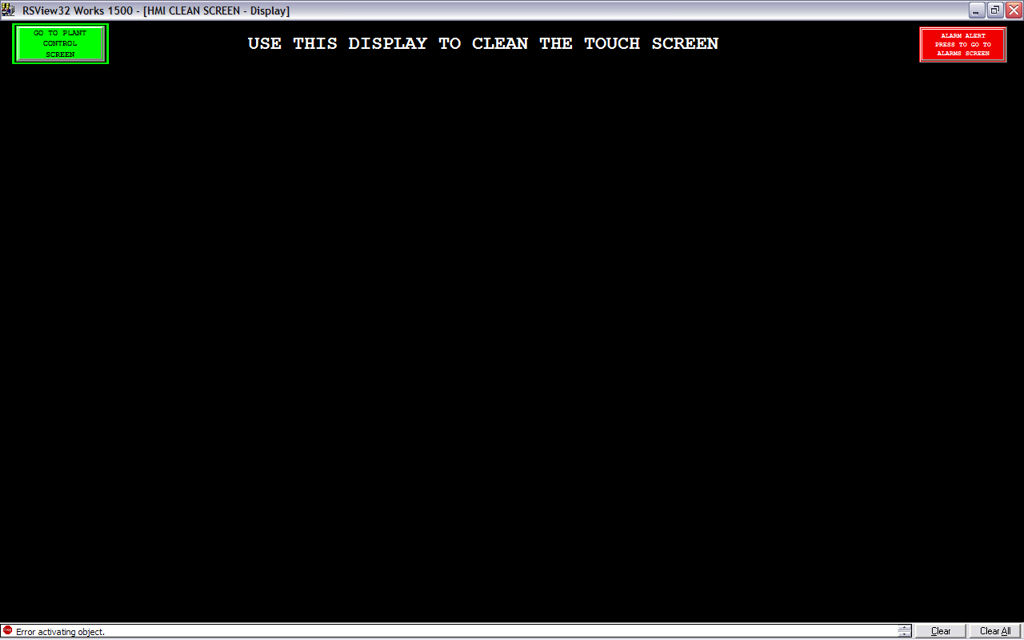

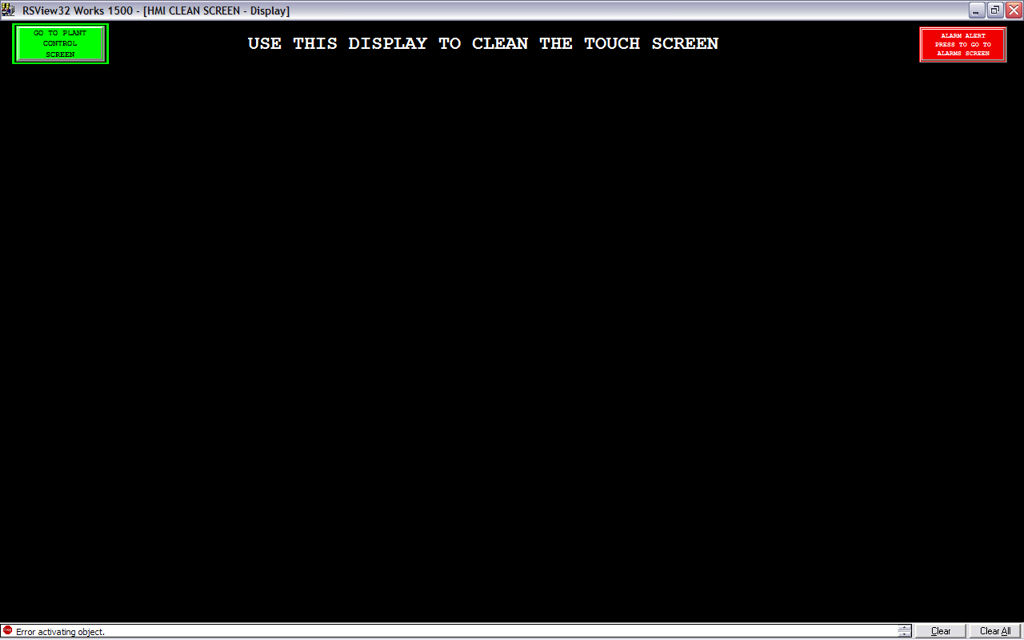

THE NEXT SCREEN PROVIDES THE ABILITY TO CLEAN THE HMI TOUCH SCREEN MONITOR WITHOUT ACCIDENTALLY INVOKING A COMMAND

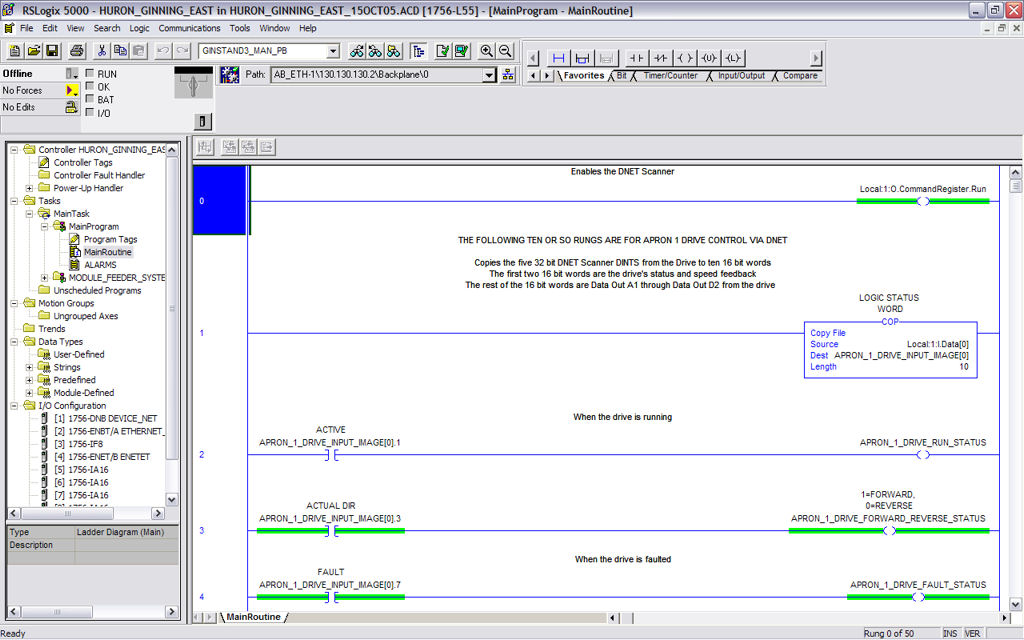

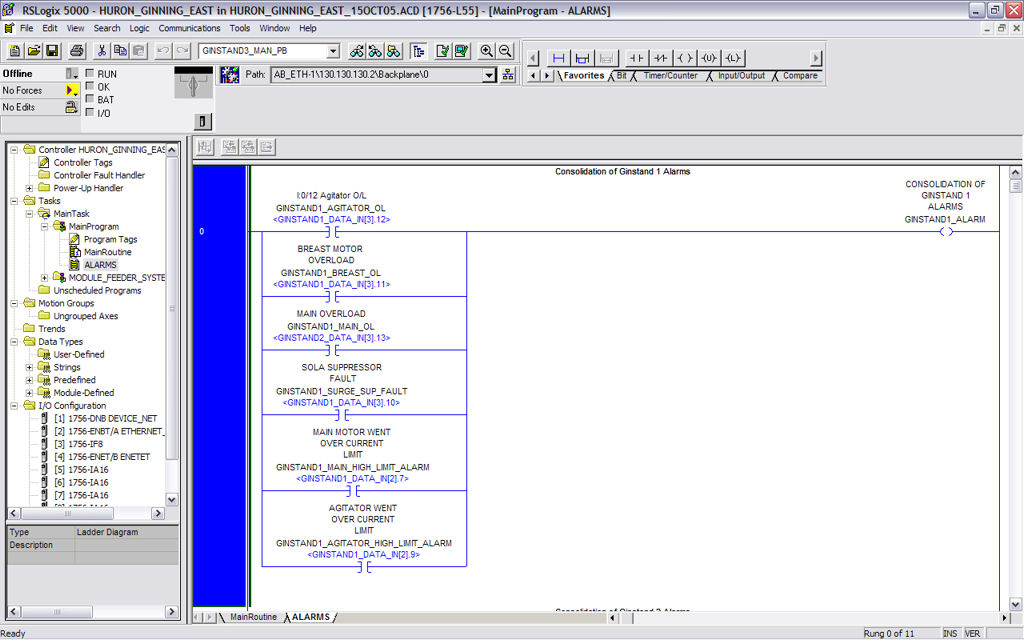

THE NEXT SCREEN SHOT IS FROM ALLEN BRADLEY RSLOGIX 5000 SOFTWARE WHICH WE USED FOR THE PROGRAM DEVELOPEMENT

JACK MCAULIFFE HELPED ME ON THIS PROJECT (TERRY'S COUSIN) AND HE IS QUITE THE GENTLEMAN AND A SCHOLAR!!

WE ARE NOT SHOWING ALL THE RUNGS OF LOGIC DUE TO INTELLECTUAL PROPERTY RIGHTS- WE JUST WANT TO SHOW A SAMPLE OF OUR ABILITIES

THE NEXT SCREEN SHOT IS FROM ALLEN BRADLEY RSLOGIX 5000 SOFTWARE WHICH WE USED FOR THE PROGRAM DEVELOPEMENT FOR THE ALARMS- DONE BY JACK

COMMENTS: CONTACT INFORMATION:

ALLIED ELECTRIC: ALLEN BRADLEY SUPPORT

SYDNEY GEE

ALAIN SPALLARD

559.486.4222

ELECTRIC MOTOR SHOP:

JON WISEMAN- CONTROL ELECTRICIAN AND MOTOR MAN

559.650.1153

(The same number will put in contact with their supply house)

CRAIG SWIFT- GE FANUC AUTOMATION SPECIALIST

THE ORIGINAL TECHNICAL CONTRACTOR WHO STARTED THE PROJECT: DENNIS OIKLE SERVICES- Thanks Dennis!

AND OF COURSE C.S.T. SERVICES- INDUSTRIAL AUTOMATION INTEGRATORS- see the front page.

CONTACT C.S.T. SERVICES FOR HELP ON YOUR NEXT AUTOMATION PROJECT! RETURN TO THE FRONT PAGE FOR OUR CONTACT INFORMATION.

RETURN TO C.S.T. SERVICES MAIN PAGE

All rights reserved by Byron K. Sanders and C.S.T. SERVICES